Eine deutsche Version dieses Reviews kann im Tacticalforum nachgelesen werden

Introduction

Like so many other visitors to IWA, I was completely surprised by the impressive booth of Acta Non Verba Knives in Spring 2019. Feeling as if it came out of nowhere, the booth was an inviting attraction with a multitude of knives in the fixed and folding segments.

Although I took a close look at the knives during the show, and also posted numerous pictures on my blog, other topics unfortunately became more important due to private and professional priorities.

However, thanks to a really excellent event, organized by Lorenzi Stahlwaren here in Vienna, I was not only able to take a closer look at the knives, but also to start an intensive exchange with the people behind the company. And these conversations brought out some exciting aspects.

Acta Non Verba Knives

Acta Non Verba Knives – ANV Knives in short – is a relatively young company that was born from a constellation of fortunate circumstances. The young knife designer Ondřej Němec started his career at Mikov Knives, but eventually realised that he was not able to develop his full potential there. I don’t know exactly how the actual meeting came about, but a contact was established with two other gentlemen: Daniel Mikula and Jindřich Prokopec. Both had decided to invest in a metalworking company and were looking for a suitable opportunity.

Long story short: ANV Knives was founded and gave Ondřej Němec the opportunity to realize his designs and the two investors Daniel Mikula and Jindřich Prokopec the chance to enter the knife industry.

They took a big risk in several ways. Normally it takes forever to establish oneself as a knifemaker, let alone as a company – if only because of the necessary infrastructure. Furthermore, finding a name, the design process etc. is a task in itself, including brand development and narrative.

All in all they had to start from scratch and create a machine park, brand concept as well as a dealer network. A scope of work that personally I would not have been able to cope with at Ondřej’s age. So I have to give him a lot of respect for that decision!

The message behind the name „Actions, not words“ and the minimalist logo design are bold. At the same time I have to say that it is also ingenious and effective.

ANV Knives offers something in all price ranges and products ,which are tailored to different user groups. Personally I had the opportunity to take a detailed look at the M311 Spelter.

Overview

The M311 Spelter was designed in cooperation with several specialized military units of the Czech Republic. In the course of this, a design was created that met the requirements of these soldiers and at the same time could be tested in their operational environments.

The full tang knife consists of a DLC coated ELMAX blade with contoured Micarta handles. The kydex sheath allows for multiple ways of carrying and is a successful addition to the knife.

Specs

- Total length: 275 mm

- Blade length: 125 mm

- Blade thickness: 5 mm

- Steel: Elmax (60 HRC)

- Handle material: Micarta

- Weight: 286 g

- Sheath: Kydex

The blade of the M311 Spelter

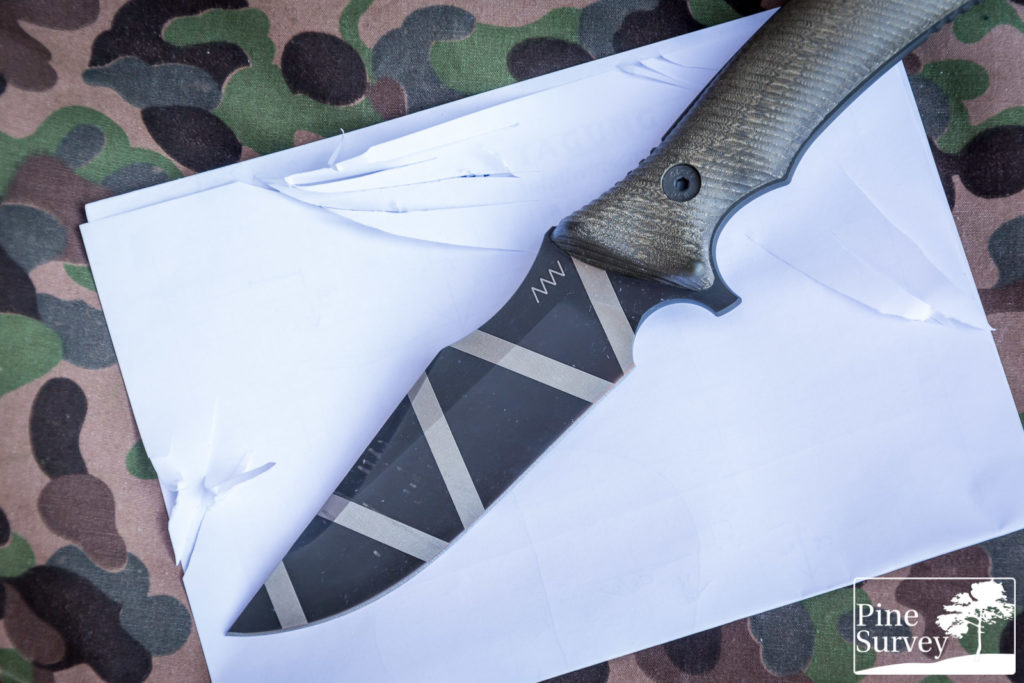

The knife is a full tang design with a clip point blade. On the back you will find a swedge in the front area, which does not reach all the way to the tip and therefore allows a strong, penetrating blade tip. At the same time the rim is sharp enough to use a fire steel.

A recess close to the handle allows a support for the thumb. This is of course a wonderful combination with the choil, which is generously dimensioned and allows for a forward grip for finer work.

The knife has a pronounced finger guard to prevent the hand from slipping forward into the edge.

The blade itself is DLC coated and available in several variations. On the one hand with a laser etched topographical map, or as in my case, with an enlarged version of the ANV Knives company logo. This gives the blade a subtle camouflage effect, as you already know from Extrema Ratio.

Company name, model name, steel and the indication of origin are also neatly engraved by laser.

The handle of the M311 Spelter

The Micarta handle is not only equipped with very fine grooves for a better grip; it is also contoured to fit the hand comfortably. I’ve been told that they took an average value of 10 different hand sizes. In fact, the grip feels extremely well even though my glove size is M and I am therefore in the middle of sizes.

At the side towards the front there is a pleasant groove for the thumb, should you wish to work sideways. Towards the pommel there is a pronounced thickening to prevent the hand from slipping.

Grooves on the front of the handle, on the pommel for reverse grip and on the underside for the little and ring finger enhance the secure grip and guarantee that the knife remains in the hand. Just in case, there is still the obligatory lanyard hole, which has been provided with a generous paracord lanyard. There you will also find a subtle glass breaker, or skull crusher.

In order to allow repairs and maintenance in the field, it was decided to fix the handles with hexagonal screws.

The Kydex Sheath of the M311 Spelter

The scope of delivery includes a neatly made kydex sheath, into which the knife snaps with a satisfying click. It must be mentioned that the sheath is not lined and the knife rattles just a little in the sheath.

A neat opening at the bottom end guarantees that water can drain off. A total of 12 eyelets offer various possibilities to mount the knife on equipment. It comes with a long piece of paracord, which serves not only as a leg strap but also for other attachment possibilities.

As a solution for the belt it was decided to sew a webbing strap with velcro and fix it to the Kydex with screws. Thus the knife can be worn on the belt without any problems. The strap can be interchanged for right and left hand carry.

If you want to carry the knife even deeper on your thigh, an optional extension is available and can be installed easily.

Workmanship

There is nothing to complain about in terms of quality. I rarely have held such a cleanly manufactured knife in my hands. The overall concept of design, materials and the sheath that comes with it fit very well. To be honest, before that I only knew this kind of quality from the US market. In this respect, something special has developed in the Czech Republic indeed!

There are no burrs on the knife, the edges have been rounded and the DLC coating with laser engraving gives a high quality impression. The micarta handle is also manufactured very clean and fits well in the hand.

Criticism at the highest level (you could consider it nagging) would be the beginning of the cutting edge in the choil. Here, the edge could be rounded off or defused. Otherwise you will get a small cut.

The sheath is also finished very nicely. The edges are smooth, you can’t see any gaps and the eyelets are set cleanly. The webbing and the velcro make a valuable impression. The shock cord for securing the grip is set with heat shrink tubing for a secure grip. I was told that they are currently looking for a supplier for thicker shock cord. So far I had no problems with the normal.

In the field

The knife has also been more than able to hold its own in use so far. Enclosed are a few pictures of the usual gripping variations. Both in the fencing grip and in the forward grip, the knife lies wonderfully in the hand. In the reverse grip it triggers downright bad thoughts, like a devil on your shoulder.

In the field itself, the blade geometry and the grind were extremely cutting friendly. The knife is supplied razor-sharp; actually, scalpel-sharp would be a better description. It slashes easily through thumb-thick hazelnut sticks. Dried beech is also no problem. The handle can be gripped comfortably even further back so that the knife becomes an exceptionally good chopping instrument.

The swedge may be a stylistic element at first glance, but the edges are sharp enough at this area that a shower of sparks can be produced from a fire steel using the right angle.

Enclosed is a minimalistic video with the impressions described above:

It should also be mentioned that the tip survived the stabbing of a tree trunk without any problems, also in combination with pushing and pulling. A not so irrelevant detail for archers e.g.

After all the mentioned work, the cutting edge had hardly lost any of its cutting ability. The dirty blade was quickly restored with soap and oil – only the sparks of the fire steel left a discoloration – which is not surprising due to the heat.

Less than 10 strobes with the sharpmaker and the knife was as sharp as before. Elmax as a choice for steel for the blade was an excellent decision.

Concluding remarks

As some of you may have noticed, my knife reviews have become increasingly rare in recent years. To be honest, the flooded market has caused me to become oversaturated and it takes several factors to get me excited again.

When I got my hands on the M311 Spelter during the event at Lorenzi Stahlwaren, it was hard to get it out of my hands. After a long time I had a knife with character and „soul“ again – a harmonious concept in total, and not just loveless assembled components.

The use in the forest did its rest to convince me of the knife and the company ANV Knives itself. The claim of the company’s motto and reality coincide, and getting to know the people in charge has done its part to thrill me.

With that being said, I hope I was able to give you a good impression of the company and especially of the M311 Spelter. Many Thanks to ANV Knives for giving me the opportunity to present you this review!

Thanks for reading!

Take care!