Camouflage and Night Vision: Expectations vs Reality part 2 – Materials & IR illuminators

Disclaimer: This is the second part of my „camouflage and nightvision“ series. For the part 1 click here.

I have tried to research everything to the best of my knowledge. However, I am not an expert in physics or textile production, so if you find a factual error, please let me know and contact me – with a reference to some research, ideally.

For more nightvision content see AND appreciate the two part series of ePig-Group. They worked hard on that one!

Update 1: since the info regarding Phantomleaf’s WASP I partial NIR capability leaked recently, I was finally able to update the article.

Introduction

In a previous article I touched upon the very basic principles one needs to consider when talking about camouflage and night vision. Obviously I do not claim to be all knowing or to have mentioned everything in part 1. However, I hope it is a working start for those diving into the topic.

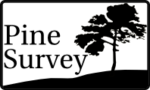

In this second article I want to look at some aspects that are closer to the actual topic: the NIR performance of camouflage prints, how IR illuminators play into the whole picture and some reality checks, when it comes to night vision. The last point is especially interesting, as the Internet and its various trends resulted in some sort of NIR madness, with the accompanying unrealistic or wrong expectations.

At this point: Once more a big Shout Out to Lunox Night Vision! These guys made it possible by providing me with a PVS-14! This was a huge leap of faith and massive help from their part! Many Thx!

Adding to that: the excellent IR reflector patches by Avustaja helped me with a) focusing the shots, and b) by providing proof of switched on IR illuminators!

Materials and NIR performance

The NIR performance of clothes and gear depends on the materials used as well as the dyes of the print. Typically natural fabrics and blended fabrics are easier to dye than 100% polyester or nylon fabrics. The latter are more difficult to work with, because of their hydrophobic properties.

While natural materials like cotton vary in reflectivity, synthetics are usually always quite bad in their NIR performance if they are not specifically treated. This brings us to the topic of NIR treatment.

Mil-Spec fabrics tend to use mainly Nylon, Polyester and Cotton fabrics as well as blends of said fabrics. Nylon and Cotton blends tend to hold colors better than Polyester fabrics which also results in a better NIR performance as one of the main factors for a good performance is the dye used. Additionally there is also the option to simply add a coating on the fabrics, which absorbs IR light, thus minimizing reflectance values.

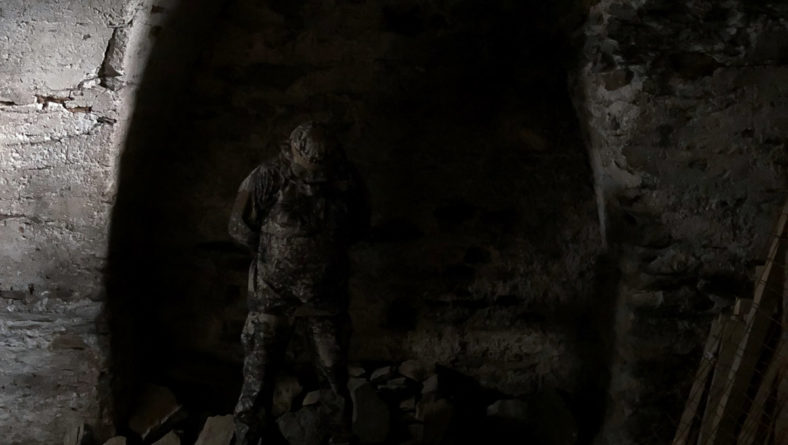

Mil-Spec fabrics are printed with specific dyes that are mixed with IR light absorbing pigments. As we have learned in the previous article, every color has a certain wavelength in the visual and NIR spectrum. The reflectance values of these colors change depending on the frequencies/wavelengths in this electromagnetic spectrum. This results in very significant curves, when put on a chart.

When looking at this chart with rough estimates, one can see how the reflectance values of the separate colors spike as soon as they enter the NIR Spectrum that starts at 750nm.

Using the right pigments, one can “color match” or “reflectance match” the IR performance of natural colors and transfer it to the printing process. In doing so, the printing of the camouflage pattern using such colors, results in a pattern that not only resembles natural colors and patterns in the visual spectrum, but also acts accordingly in the NIR spectrum of nature. Simply put: a color matched green or brown color will reflect IR light the same way as a similar colored leaf or branch.

Of course there is always the option to simply apply an NIR absorbing coating to the fabrics, but as soon as this is washed away, so is the NIR performance. A simple coating only serves as general absorption of IR light in order to decrease reflectance. As a result, color contrast and/or separation might suffer, depending on the colors used.

That being said, at some point the NIR properties of every fabric will lessen, depending on how the fabrics are used, washed or altered. For example: optical brighteners in washing detergents, high temperature washing cycles or applied colors/dyes can result in a negative effect. But also natural exposure to light and the elements have an impact.

Last but not least, and this is one of the more sophisticated and longer lasting treatment processes: besides the dyeing process, it is also possible to treat the yarns themselves with the necessary pigments, resulting in a fabric that already features NIR properties.

Inherent NIR properties and modern dyes

As already mentioned, natural fabrics tend to perform better in the NIR spectrum than synthetic ones. Cotton for example has inherent light absorbing properties because of the spiral fiber structure, contrary to the rounded and smoother fiber of Nylon.

This has the interesting effect that fabrics with high cotton content showcase low reflectance values under NIR – assuming that said fabrics were not dyed or otherwise treated with optical brighteners, or reflective pigments.

An interesting example are old Zeltbahns and WW2 Ponchos which work rather well in the NIR spectrum because of said fabric inherent properties.

There are other examples of non Mil-Spec fabrics, prints etc working remarkably well in the NIR spectrum. One of which would be the camouflage pattern “Kreuzotter” by Novritsch, which was printed intentionally without NIR treatment as it is solely intended for Airsoft. The fabric for their uniforms is 65/35 PolyCo (Polyester/Cotton) and is being printed overseas. These uniforms perform remarkably well under night vision, with the caveat that color separation and contrast is not as good as that of mil-spec prints. However, this does not include the Nylon fabric used for their gear, which does not work under NIR.

Similar results can be found in other airsoft patterns using 100% cotton.

[UPDATE 1 – as the info finally leaked]

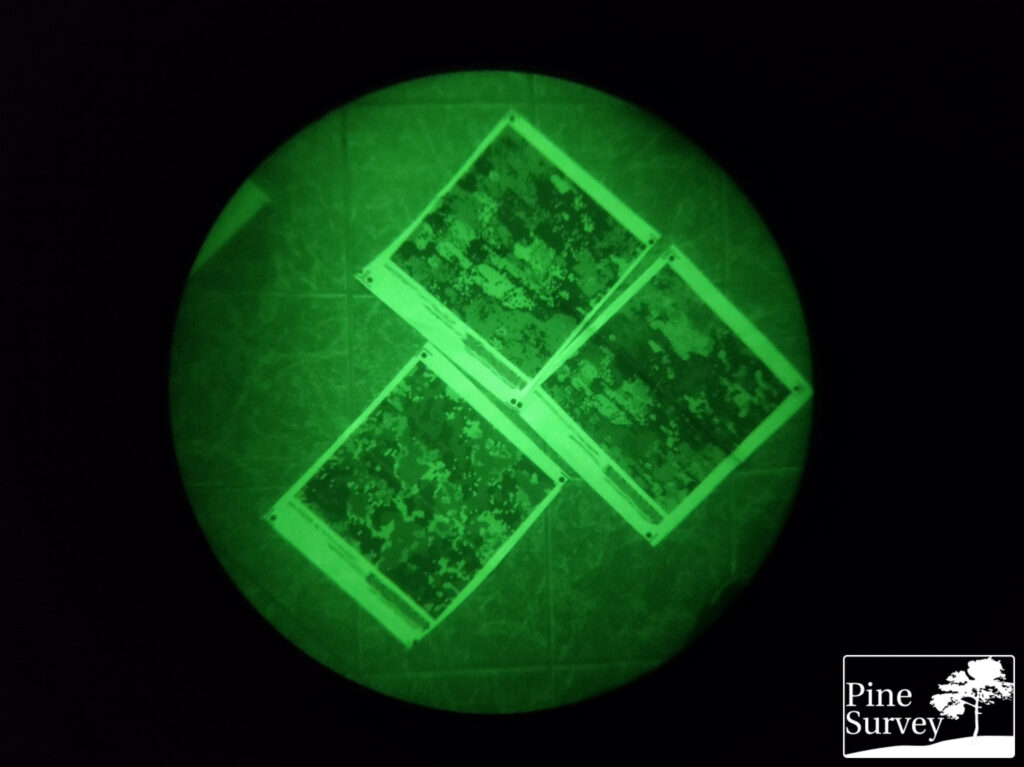

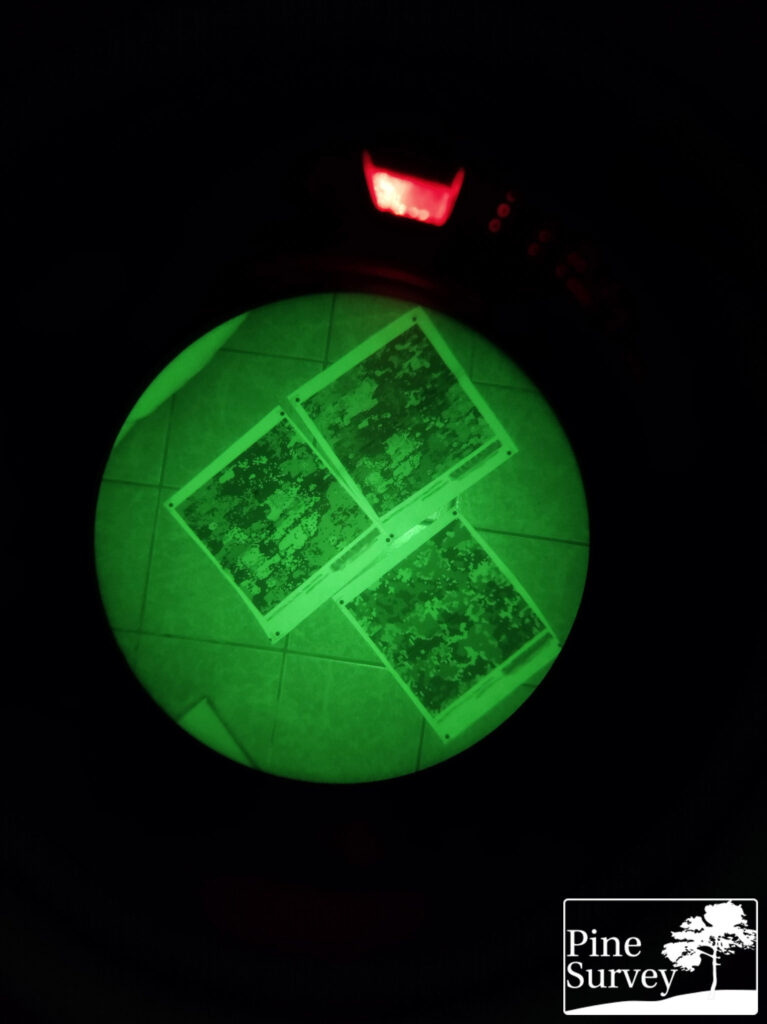

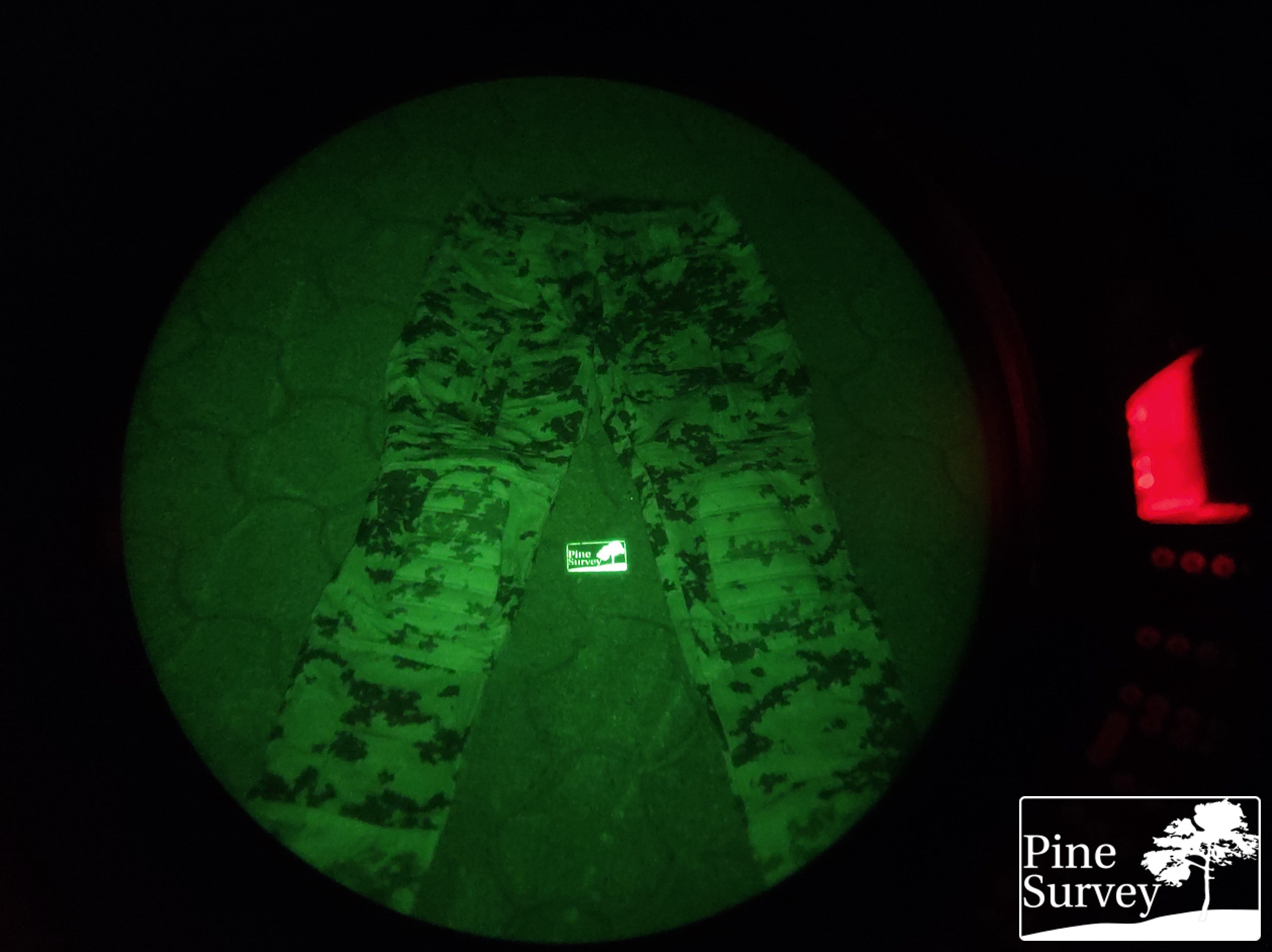

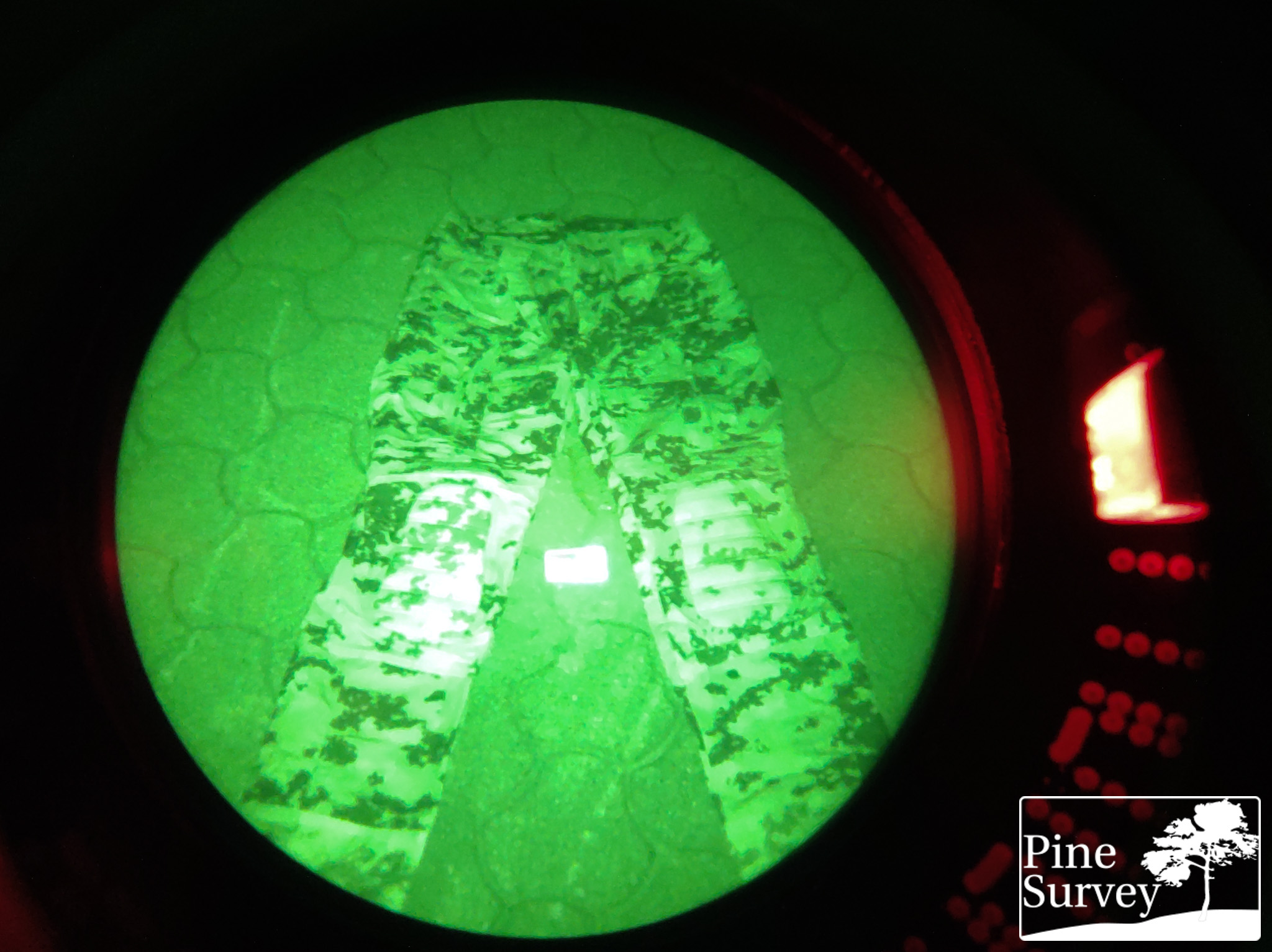

On example is Phantomleaf’s WASP I family of camouflage patterns, which was introduced together with Mil-Tec. The fabric inherent properties, as well as the dyes used by the printer resulted in an unintended NIR capability, that is also enhanced by Phantomleaf’s tendency to design high contrasting patterns.

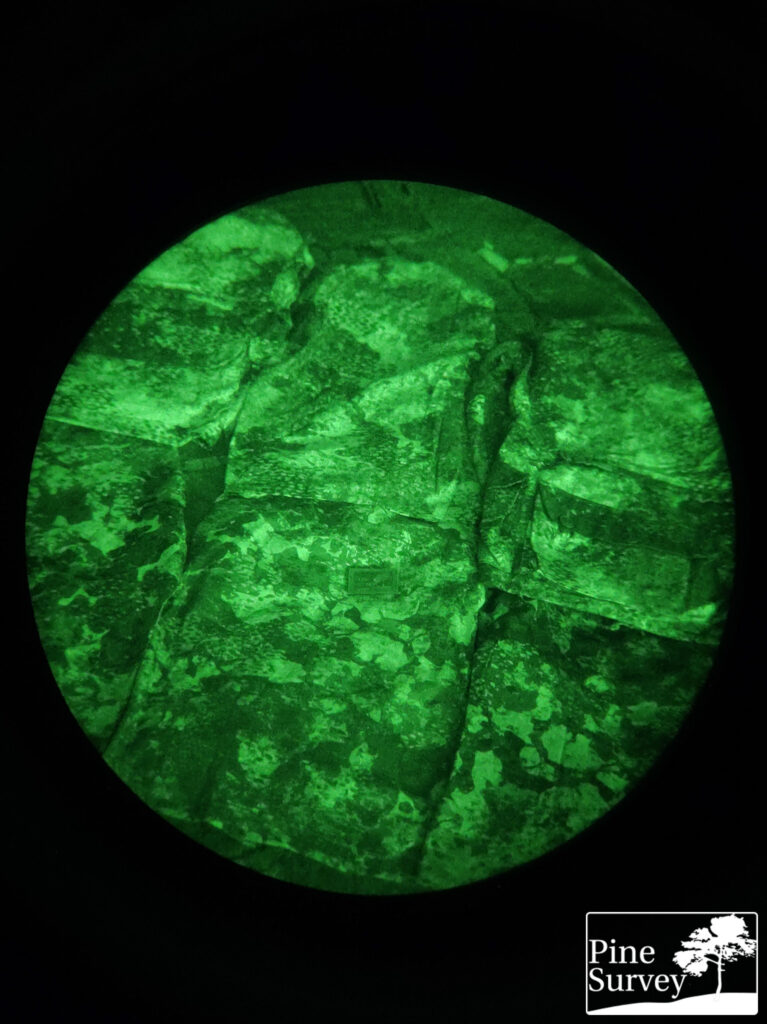

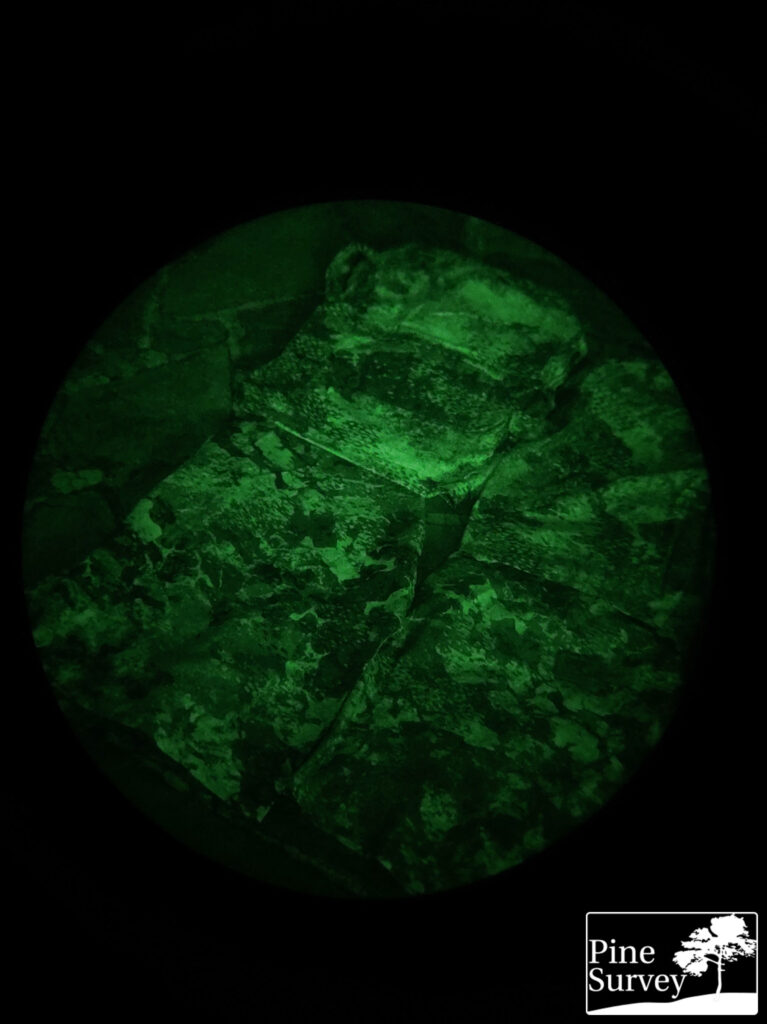

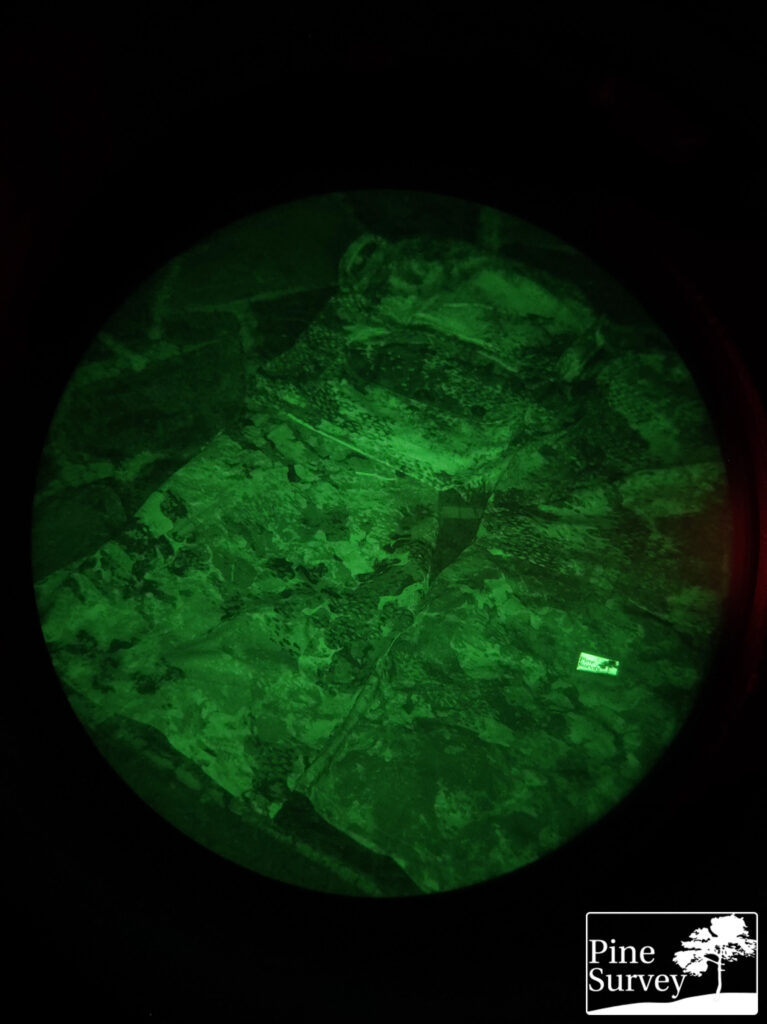

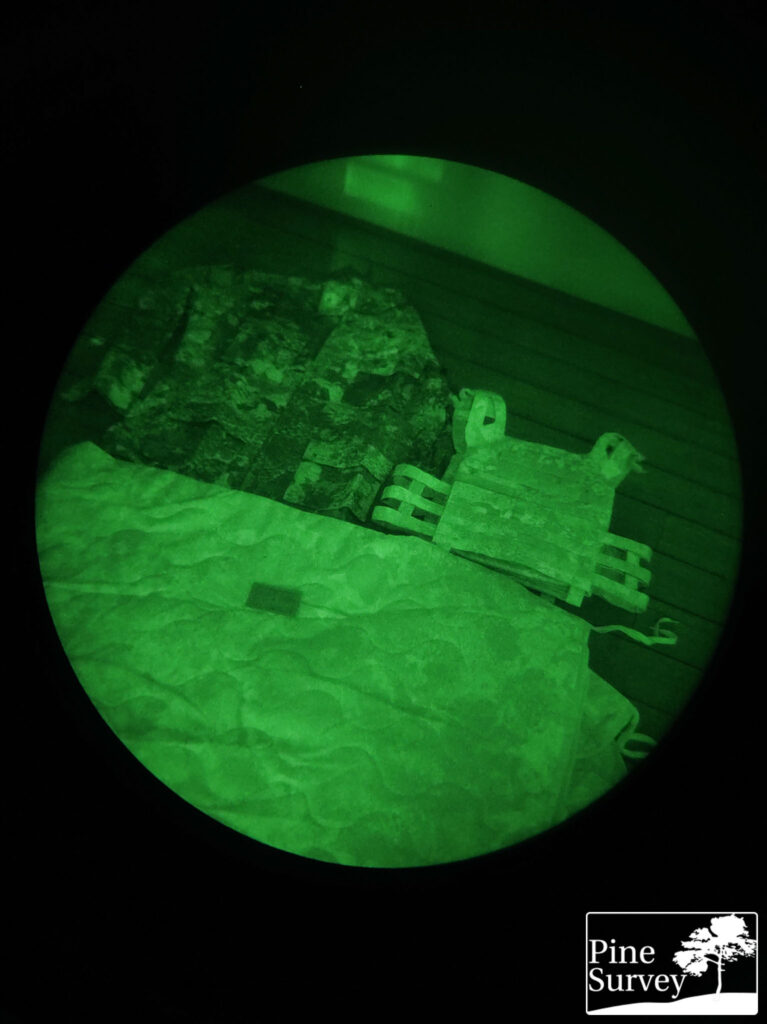

WASP II below (not NIR treated)

As you can see on the pictures, the BDU uniforms have a rather good NIR performance. In comparison to the WASP II family, they perform to a lesser extent under night vision, as the colors are not specially dialed in for NIR, but the overall performance is surprising.

Big HOWEVER… just as mentioned above, this does not include the gear or other polyester based items by Mil-Tec.

[End Update]

Modern dyes have come a long way. However, I do not have enough insight into the industry to understand the exact chemistry and why modern dyes and colors can provide NIR capabilities. One explanation could be that the printing companies use similar or the same dyes for military productions as for civilian ones.

So far I have found good performances in camouflage prints of Carhartt and even digitally printed fabrics from Spoonflower.

ATTN.: Handle these remarks with care – these are sampled findings by myself that can represent particular batches of prints, sheer luck etc. If you are looking for reliable NIR compliant solutions, take these statements with a grain of salt. That being said, let’s cover some reality checks.

IR Illuminators – a reality check

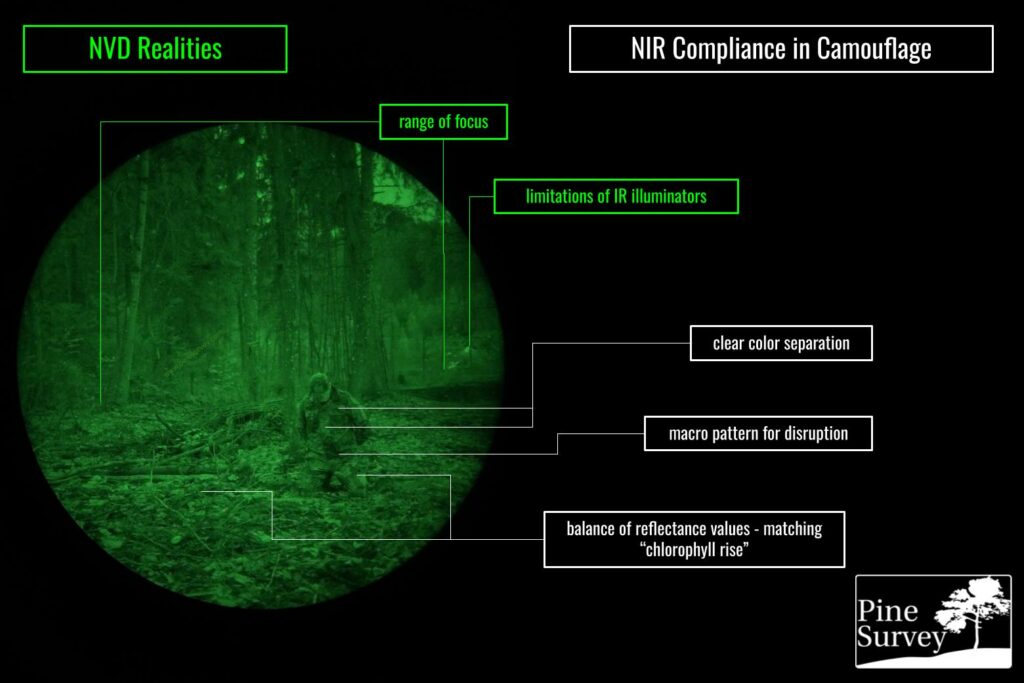

Most NVDs have an in-built IR illuminator to provide an extra light source for situations in which ambient light is too scarce. Especially during urban combat situations, in buildings, tunnels and the like, these are necessary to make NVDs work at all.

Having said that, one of the main operational uses is clear. The IR Illuminators basically function like flashlights for the users, and act as such, with the exception that they are only visible in the NIR and not the visual spectrum. They have limited range, cast shadows like regular flashlights and everyone else who is using an NVD in the vicinity will be able to spot the IR light source as well.

Built-in IR illuminators only have a range of a few meters. Of course there are flashlights with an IR function, that are able to throw a beam with a longer and wider range. But again, these are visible to everyone with night vision capability and as a result the use has to be carefully considered.

When it comes to NIR treated gear and clothes one has to consider the following aspects as a result:

- There are fabrics that are NIR compliant under regular night vision as well as when illuminated by an IR illuminator.

- Then there are those which only work under regular night vision, but experience high reflectance values (the ominous “glow”) when highlighted by an IR illuminator.

- IR illuminators have similar blinding effects like flashlights. So the higher the gain setting of the NVD or the closer the object, the brighter it is. So fabrics might appear to “glow” even if they usually would not.

That being said – consider the following:

In situations when an IR illuminator is being used – urban combat, close quarter combat, extremely low/no light situations etc. – is NIR compliance of camouflage patterns still relevant?

- In CQC and urban combat you have the opponent already within a range where camouflage is not a topic besides IFF, with plenty of other objects and surfaces in close proximity that shine as well under NVD.

- Under extremely low light conditions, the field of view or better said, the distance you can actually see, is so limited that you would not see anyone “glowing” anyways. And if the opposing party is using NVDs as well, you are only giving away your position.

Concluding remarks

This article features several bold statements and reality checks some might consider philosophical. So any constructive feedback is welcome and will be added, if constructive and necessary.

As stated above there are several ways to make fabrics NIR compliant: in the simplest way with a coating, the more sophisticated procedure with dialed in colors, using pigments and specialized dyes, and by dyeing and treating the yarns of the fabric itself.

That being said, it is interesting to know that natural fibers like cotton feature an inherent light absorbing property that makes some clothes NIR compliant, even if not specifically “treated”. However, these items will not feature the same color separation and contrast needed for the camouflage pattern to act as intended. This has also to do with modern dyes and the accidental use of the same or similar colors used for military fabrics.

Summing all of this up and adding the findings of pt 1, one can say a good NIR compliant camouflage pattern is one that:

- features a clear color separation of the pattern colors, thus making the pattern work in the NIR spectrum as well as the visual spectrum.

- finds a balance of reflectance values to mimic the performance of nature. It is not working if it absorbs too much IR light and becomes a dark blob. And it is not working, if the reflectance is so high that it appears to glow.

This in combination with the above mentioned color separation makes a camouflage pattern “fit in” in the intended environments.

Having said all of this, one cannot emphasize enough that NIR compliance and reflectance values under the beams of IR illuminators are topics that have to be considered rationally and logically. One does not need NIR compliance when hidden in a field 100m away. In CQC situations (the scenario that probably most users buy NVDs for) you will be either hidden, behind an obstacle or so close that NIR compliance is the least of your problems.

Everyone that has used NVDs for patrolling, observations or hunting will know their limitations. This would be certainly a topic of its own, besides the NIR compliance of camouflage: e.g. focus adjustment, eye strain, identifying targets at longer ranges, light and shadows etc…

Without a doubt, NVDs are important tools during night time and low light environments, but technology is advancing fast and so is the availability of other/better optronic devices, which are leveling the playing field.

And that is when thermal vision comes into play…

Stay tuned…